Austempering Processes - ADI

Tempering, Carburizing, and Carbonitriding Processes.

Heat treatment is carried out to improve the mechanical properties of metal alloys. By heating and cooling metal alloys under controlled conditions, it is possible to modify their hardness, toughness, strength, and ductility.

Heat treatment is essential for optimizing the performance and durability of metal alloys in various industrial applications, increasing their lifespan and contributing to cost reduction with raw materials.

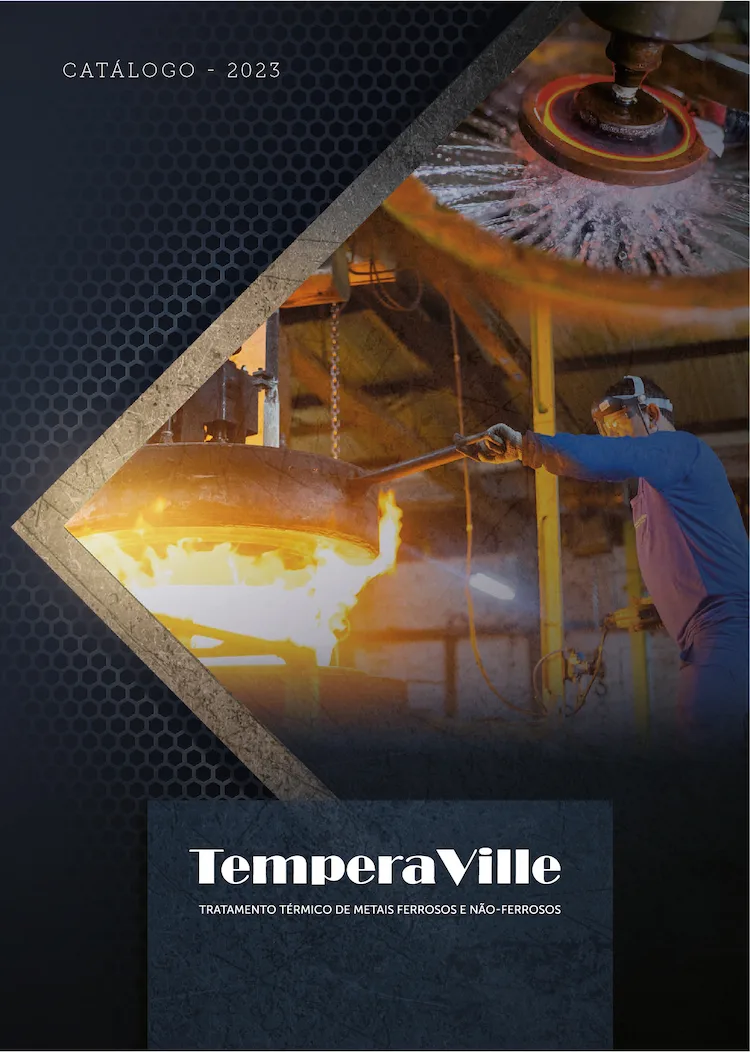

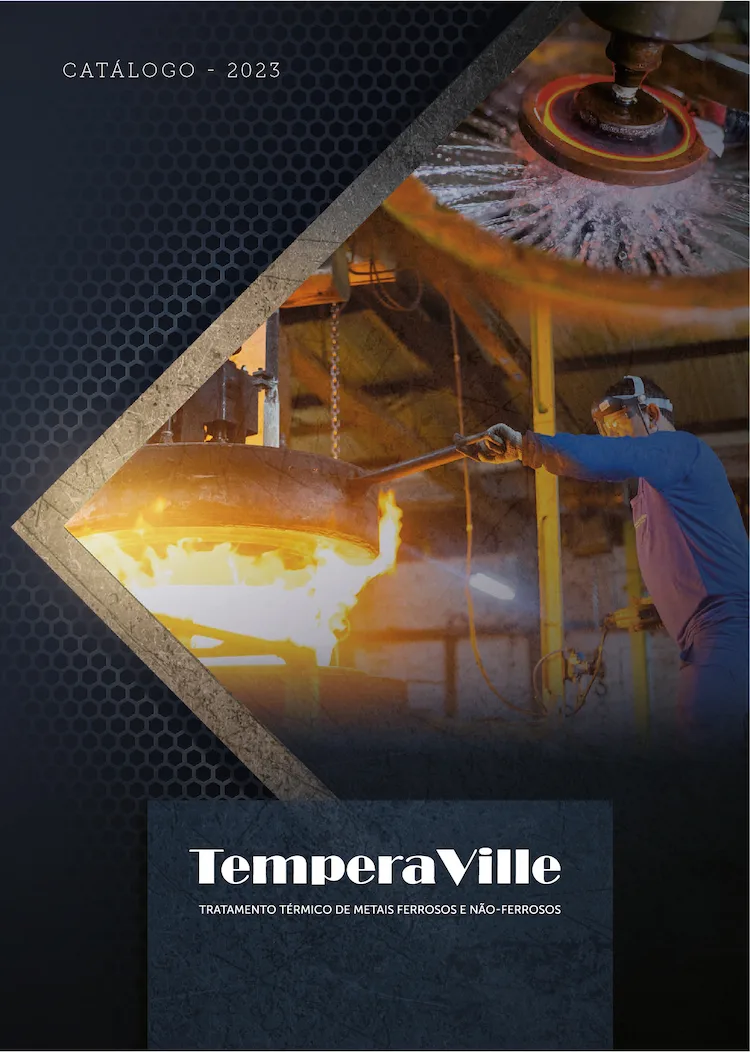

Temperaville specializes in thermal processes for ferrous and non-ferrous metals. Our expertise allows us to determine the best thermal cycle for your parts, considering the least dimensional deformation, prevention against cracks, and increased lifespan of materials.

It consists of homogenizing and refining grains, with the aim of increasing or reducing hardness.

Eliminate hardening, regularize rough fusion structures, reduce hardness, improve ductility and machinability, eliminate effects of previous thermal or mechanical treatments.

Remove residual stresses, increase dimensional stability, increase resistance to fracture of welded areas.

Thermochemical process aimed at increasing wear resistance through surface hardening, resulting in hardened layers with carbon content between 0.80% and 1.0%.

A modified form of Carburizing with the introduction of Ammonia, which adds Nitrogen to the carburized layer; this results in high hardness and wear resistance superior to Carburizing.

Increase the hardness of materials, their resistance and yield limits, through the obtaining of Martensite.

Its purpose is to increase the ductility and shock resistance of tempered metal alloys.

Isotermic transformation, which allows obtaining Bainite, or Ausferrite in the case of nodular irons (ADI), constituents more ductile and tenacious than Martensite.

Eliminate retained Austenite and transform it into Martensite. After this process, the parts must be Tempered to avoid brittleness.

Performed in Aluminum and Copper alloys, whose mechanical properties and dimensional stability will be elevated by Precipitation.

Our processes are carried out with total focus on quality. We apply the concept of Full Time Control at each stage of production. That is, all furnaces have graphic monitoring of the heat treatment curve, and our operators follow a rigorous checklist of calibration during the processes.

Enter your details below and click on download to receive the catalog with all our services!

A Temperaville tem expertise em tratamentos térmicos. Entre em contato para saber como podemos atuar junto com você, no seu negócio!

With over 20 years of experience, Temperaville is a company specialized in thermal processes for ferrous and non-ferrous metals, consolidated in the Santa Catarina market.

Desenvolvido por Pixel Perfect